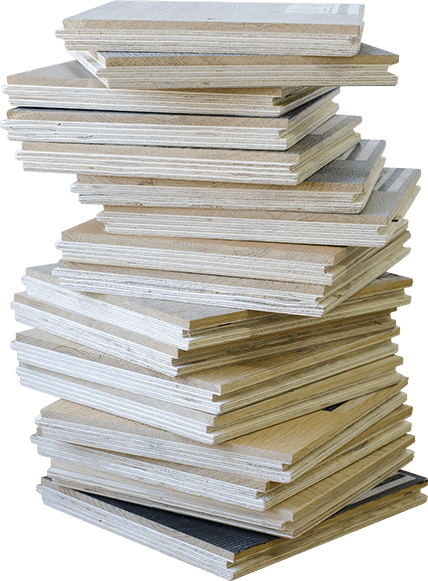

Not all engineered hardwood flooring is created equal. Variety in durability, stability, or simple quality is common across all different brands. One common variant is a sawdust or plywood core layer. Both are common, although they result in very different flooring. And while engineered hardwood floor is a smart choice for your home based on several factors, it’s important to make sure the materials used in your floors are high-quality. We break down which core layer is the strongest and ultimately what you should look for.

What’s the core layer’s function?

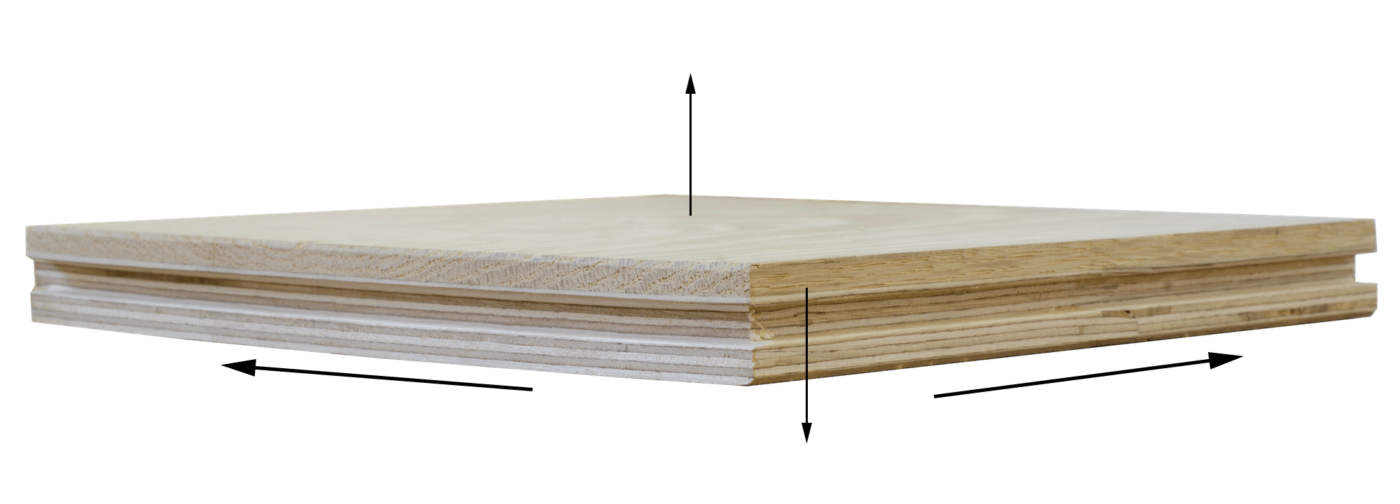

In engineered hardwood flooring, the core layer supports the top layer of hardwood. While it’s important to use a high-quality plank of hardwood for your flooring, it’s equally important to support it with a strong and reliable core layer. Two options for this layer are plywood and sawdust.

Sawdust core layer

A sawdust core layer is a popular new method of creating an engineered hardwood flooring core. With this method, imperfect hardwood is ground into sawdust and combined with resin, then compressed at a high temperature to create High Density Fiberboard, or HDF. This core is similar to a more dense particleboard and its strength depends on how strong the wood used to create the sawdust is. Because the HDF is dense, it can often resist small amounts of moisture damage without swelling.

HDF is moisture resistant and stable, giving it an edge over lower quality plywoods.

Plywood core layer

Plywood core layers are traditional for engineered hardwood flooring. With this core layer, pieces of plywood are glued in a criss-crossing pattern and then compressed. This means that whenever there is a pull on the floor, the plywood pieces evenly distribute that stress, leaving your floors securely in place. It’s also important to use a high-quality glue, such as a water boil proof (WBP) glue, to bond the plywood together. WBP glue helps create a moisture resistant core layer.

However, the type of plywood used makes all the difference. Weaker wood types, such as birch, won’t be as strong as HDF. But when you use a stronger plywood, you can create a better bond between the layers with more resistance to movement. This will keep your flooring in place more securely. Ultimately, when you use a strong plywood, a plywood core layer is stronger than sawdust.

Premium plywood

Just like the flooring itself, not all plywood is created equal. Premium plywood is the best available plywood, and flooring brands using exclusively premium plywood for their flooring’s core layer care about providing the best quality possible. This type of plywood creates a core layer that’s stronger, more durable, and more resistant to temperature and moisture changes than sawdust.

Looking for engineered hardwood flooring with a plywood core layer?

Contact us! Our flooring uses 100% premium plywood so we can guarantee a strong and durable core layer. We want your floors to last a long time and stay in great condition just as much as you do, which is why we’ve engineered our floors to be the highest quality at our price. Plus, all of our flooring is completely custom, so you can make your flooring dreams come true! You can view our past projects here